|

| |

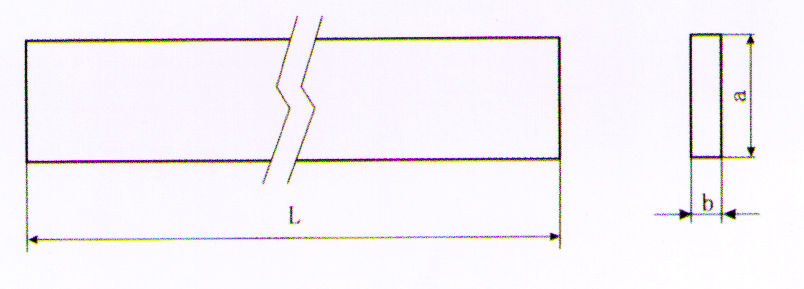

| Dimensions and tolerances abA&B allowable deviation LL allowable deviation2~52~4+0.7~+0.3<500~+3.05~102~4+0.8~+0.450~1000~+3.510~152~4+1.0~+0.4100~2000~+515~202~4+1.2~+0.4200~3200~+6 | ||

Main grades, properties and uses of alloy profiles are recommended:

grade | binder | density | hardness | strength | grain size | use |

g/cm³ | HRA | N/mm² | μ | |||

K10 | 6 | 14.9 | 92.5 | 2500 | 0.6 | It is suitable for making various cemented carbide integral tools for machining chilled cast iron, heat-resistant alloy steel, non-ferrous metals and non-metallic materials. |

K20 | 8 | 14.65 | 88 | 2350 | 2.4 | It is suitable for making various cemented carbide integral tools for machining chilled cast iron, heat-resistant alloy steel, non-ferrous metals and non-metallic materials. |

K30 | 10 | 14.3 | 87 | 2410 | 2.4 | Wear resistance and willfulness are good, suitable for making various hole processing tools, with good versatility. |

K30 | 10 | 13.65 | 85 | 2450 | 2.4 | Ultra-fine alloy, suitable for making various integral tools for processing non-ferrous metals, non-metals such as glass-reinforced composite materials, special resins, and super-hard plastics. |

- View: